Foshan Tecon Package Machinery CO., LTD

is a high-tech equipment manufacturer. In 1996,We designed the first production line for Karft paper bag, and now we are top three listed in the world in this industry and the only one in China able

to design and manufacture the whole production line of bottom pasted paper bag.

After-sale service

1.Provide training during and after the commissioning at the buyer site.

2.One year warranty period from the acceptance at the buyer site.

3.Provide life long technical services and effective solutions.

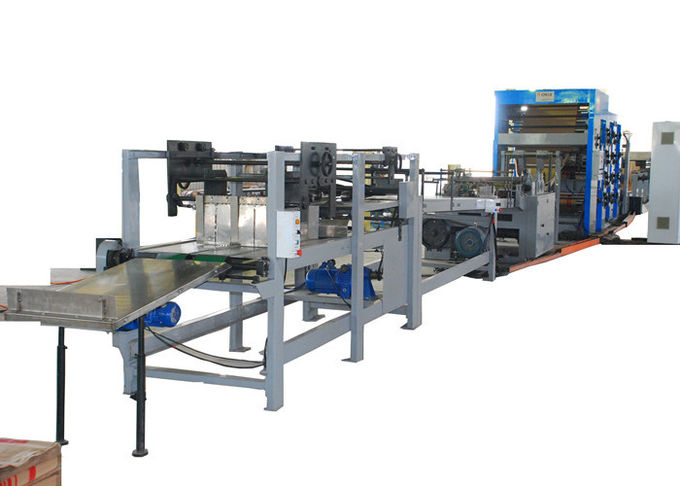

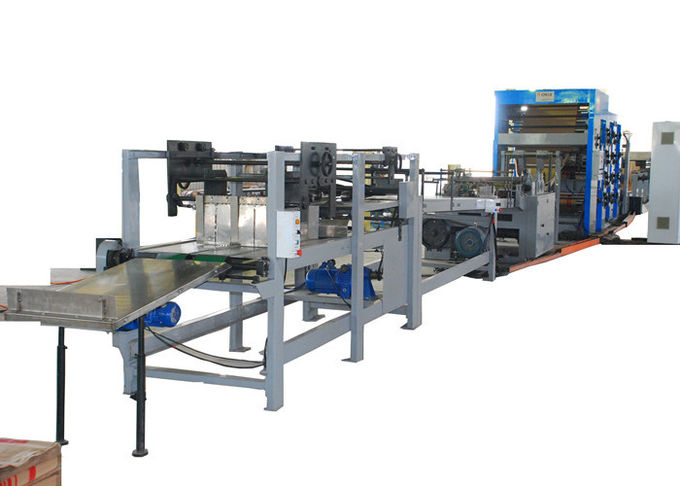

- Features of our full-automatic paper bag production line:

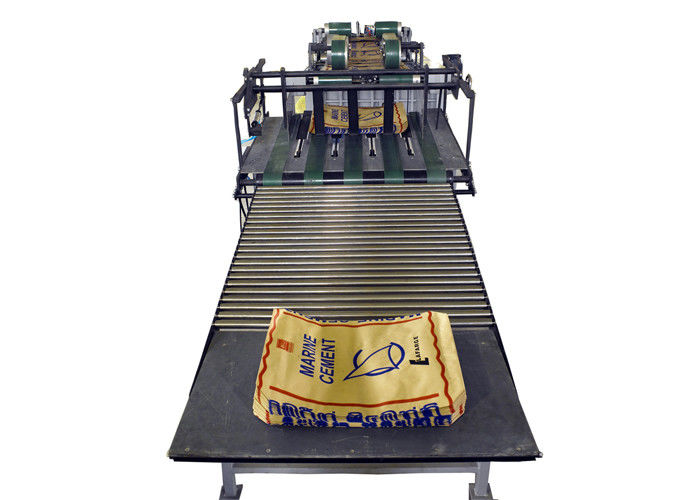

1. Flat & glued bottom with filling valve;

2. Different types for cement, chemicals, foods, tea, etc.

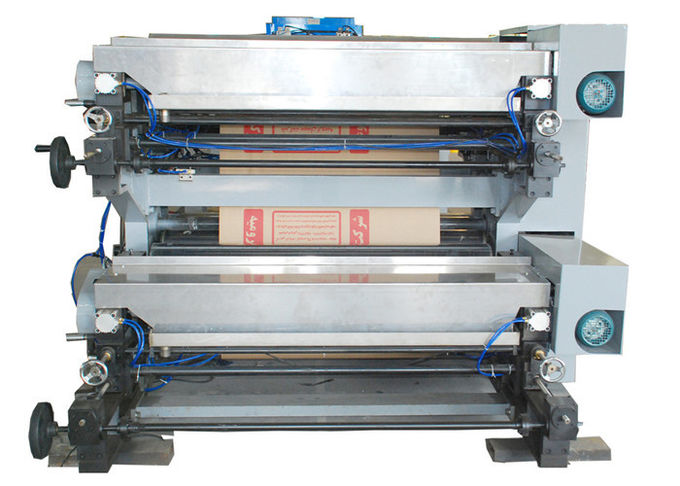

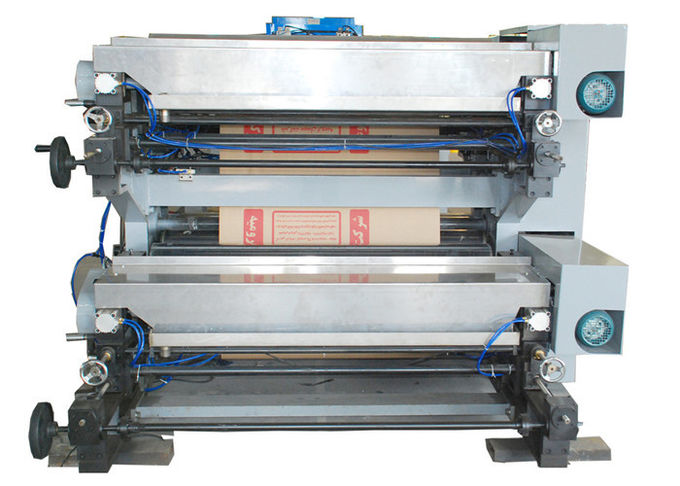

3. 2-color automatic printing

4. 2~4 paper layers, with one extra PE/PP film available

5. 35~50 million bags/year

6. Servo system control or PLC control available, integrated with Photoelectric & Pneumatic control system, Siemens electrical system

7. Full technical service for installation, training and maintenance

8. Full solution for factory construction and materials purchase.

Specifications

1) Cement paper bag making machine.

2) Prompt and professional after sale service.

3) High speed Automatic Cement Paper Bag Making Machine is professional machine for valve bottom pasted bag. The bags are widely used for packing powder materials or particulate materials, such as cement, chemical raw material and grains.

Technical parameters of our production line:

ZT9804 Tuber Machine

Operating condition

| Working hour |

22 hours/day |

| Design temperature |

0~40℃ |

| Design humidity |

MAX. 95% |

| Number required |

1 unit |

| Model name |

ZT9804 |

Performance

|

Speed

|

130~150 tubes/min(Depends on paper quality, number of ply and

operators’ skill.)

|

| Tube length |

670~1035 mm |

| Tube width |

420~600 mm |

| Space between tape steps |

20 mm |

| Tube Cut Length |

670~1035mm |

| Number of ply |

2~4 paper + 1 PP/PE(Please specify if you need paper bag with PP film) |

| Diameter of print roller |

ø144~ø314 mm |

| Printing width |

1300 mm(MAX) |

| Paper reel width |

860~1260 mm |

| Paper reel diameter |

Max. 1, 300 mm |

| Air consumption |

1,100L/min |

| Main drive motor |

30kw |

| Size of whole set |

34.3m×2.4m×2.7m( L×W×H) |

| Total weight |

30 T |

Composing of the production line

ZT9804 Tuber Machine

| Name |

Quantity |

| 4-color printing machine |

1 |

| Paper reel stands |

1 |

| Paper web guider |

1 |

| Automatic paper rectifier |

1 |

| Auxiliary paper driver |

1 |

| Perforation machine |

1 |

| Latitudinal gluing machine |

1 |

| Longitude gluing machine |

1 |

| Tubes forming unit |

1 |

| Driving tearing-off |

1 |

| Delivery & counting line |

1 |

| Electric control system |

1 (Schneider, German) |

| Air compressor |

1 |